Stairlift

This was our two-quarter Senior Capstone Project, provided to our team by Volkswagen. The challenge was to, in less than 19 weeks, design a single entrance for a high clearance school bus that accommodates users with and without disabilities.

Overview

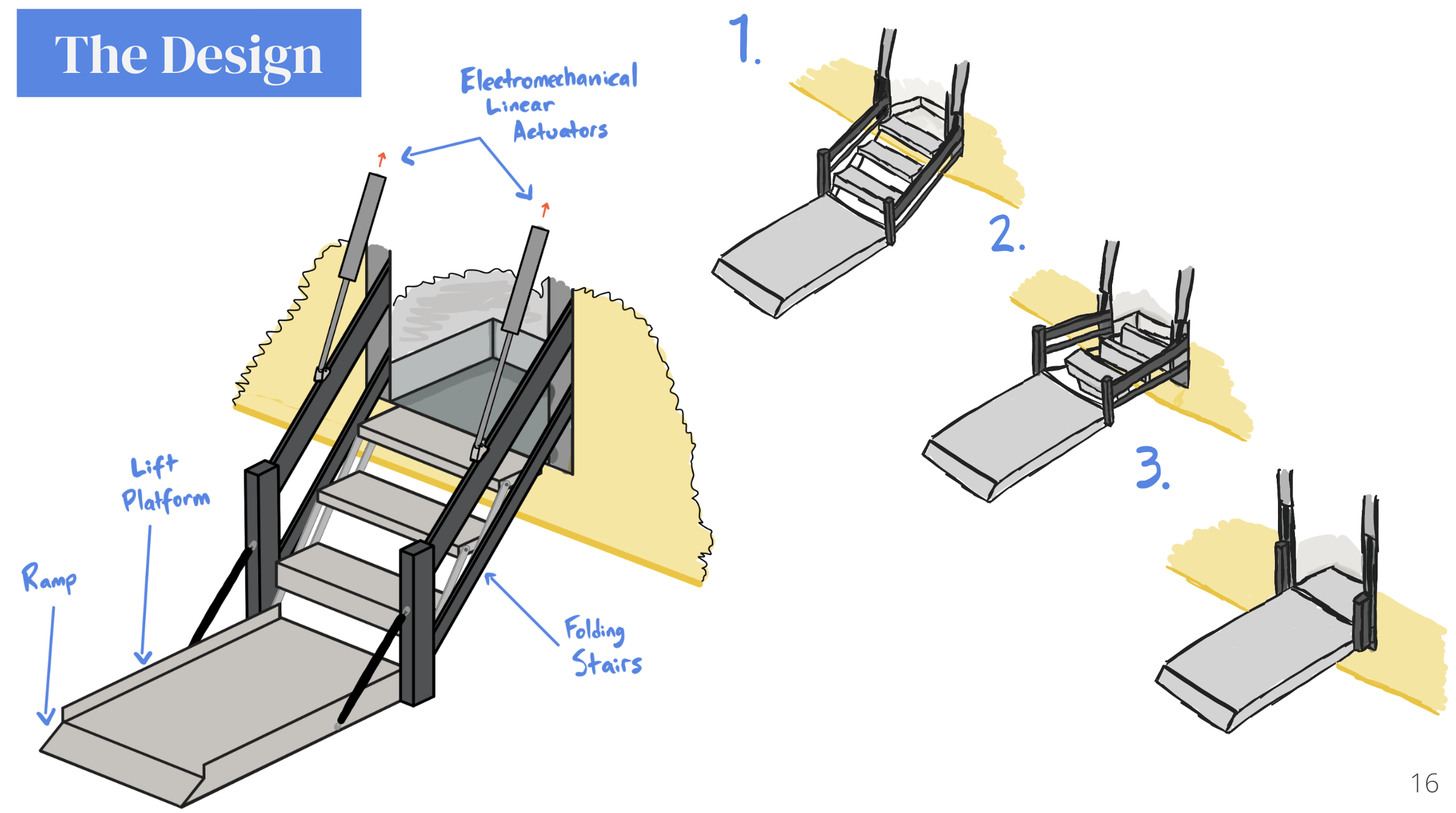

This device combines the accessibility of a lift with space-saving steps to provide a safe, speedy and inclusive entrance for people with and without mobility-related disabilities. Linear actuators quietly raise a lift in a smooth arc path while collapsing a staircase into the floor of the bus.

Solution Choice

The prompt was immensely open-ended, but while there were a variety of solutions we explored, such as telescoping ramps and stairs that collapsed into a ramp, we decided to pursue the Stairlift concept due to the high-clearance of the bus, confidence in ADA Compliance, and the tight timeline.

Solution Effectiveness

When conducting user interviews with wheelchair users after creating our initial prototype, we found that our solution tackled several key issues surrounding existing lift systems in buses including mechanism transparency (easy to see how it is working) as well as the absence of jerkiness and noisiness (via a single, silent arc path).

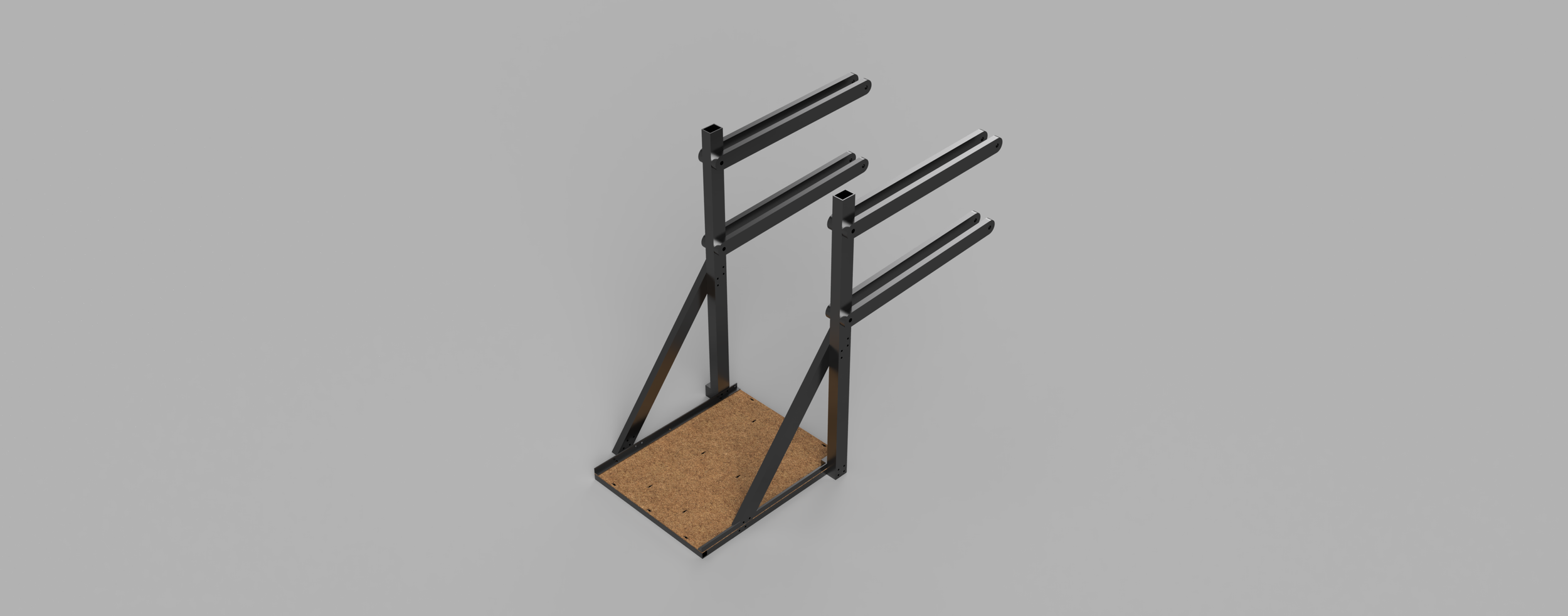

Design Features

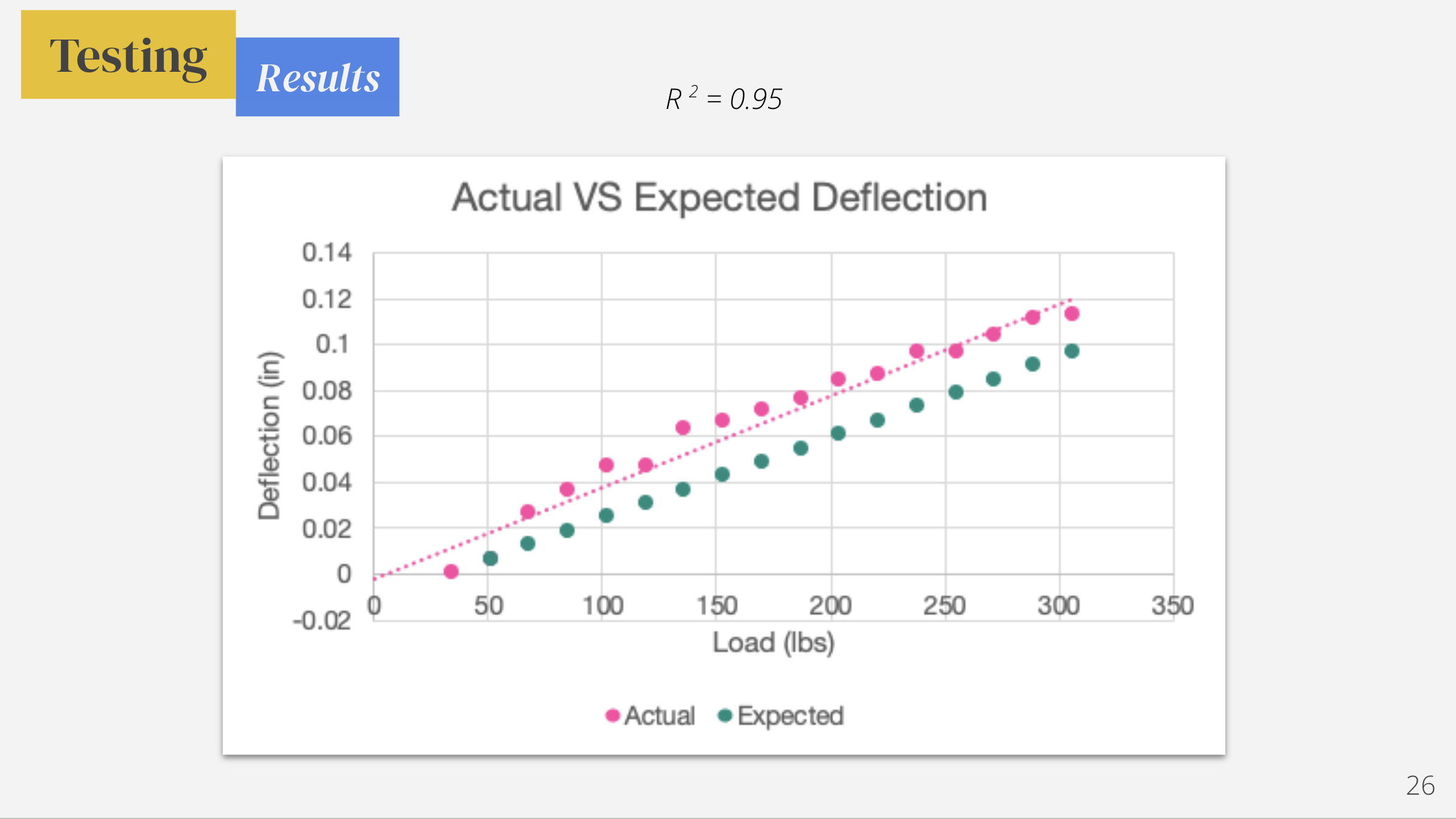

Tested total dynamic load support of at least 500 lbs at half scale

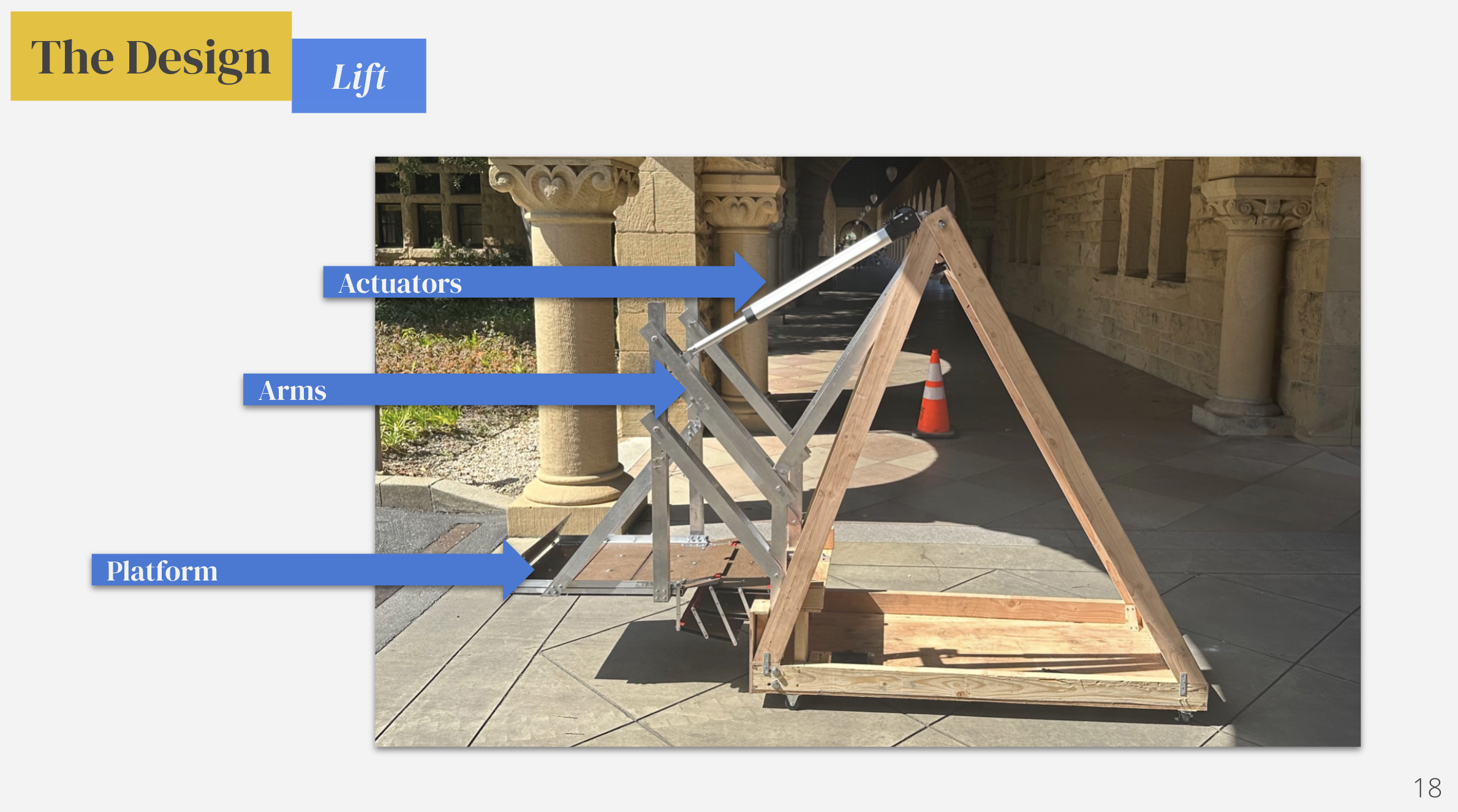

Powered by a pair of electromechanical linear actuators, each with a 20” stroke rated up to 400 lbs.

Synchronized via internal hall effect sensors

Thresholds that fold up to become ADA-compliant barriers

30 second lift in an arc path, faster than many current bus lifts in operation.

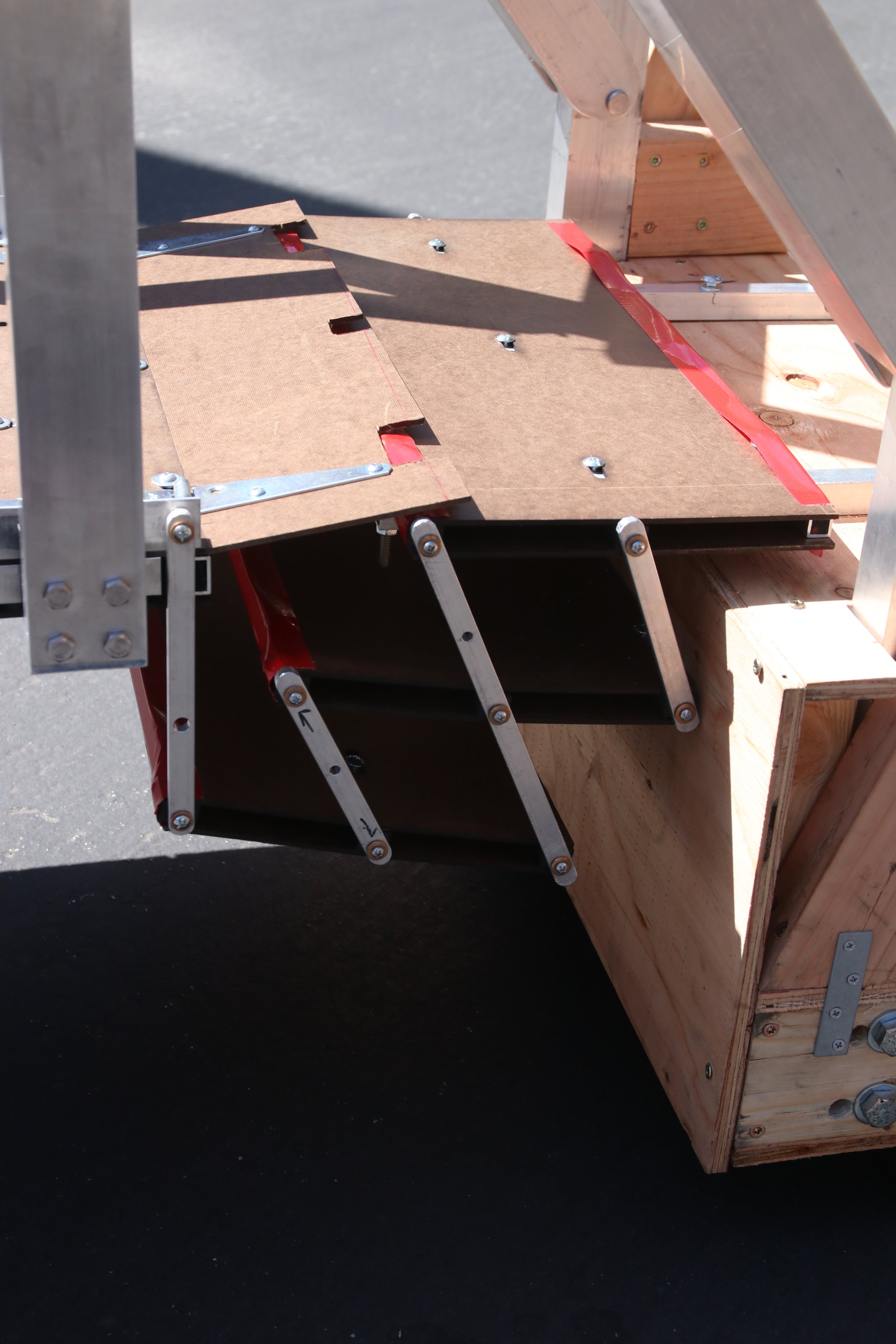

Materials and Manufacturing Process

The lift assembly and internal components of the staircase are made of aluminum square tubing, which were all precision machined on a manual mill. The floor panels of the lift and stairs are made of lasercut hardboard.