Heated Faucet

This was the final project in Computational Engineering (ME 123). The goal was to design an in-situ faucet heater that instantly produces warm water at a reasonable pressure while still being small, safe, and efficient. ANSYS Discovery was used to run thermal and fluid simulations while the faucet itself was iteratively designed in Autodesk Fusion 360.

Overview

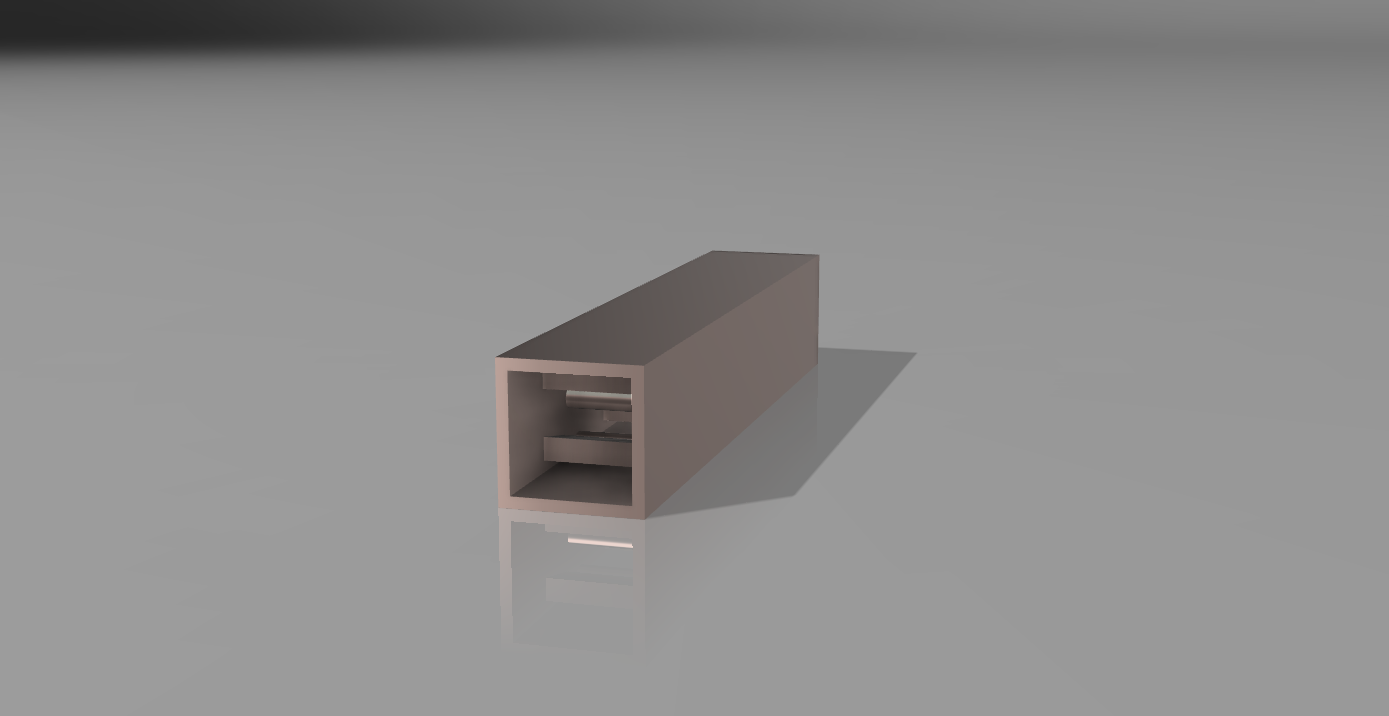

The Heated Faucet is composed of an internal internal heating element and a stainless steel shell with a vacuum layer to maximize maximize safety and thermal efficiency.

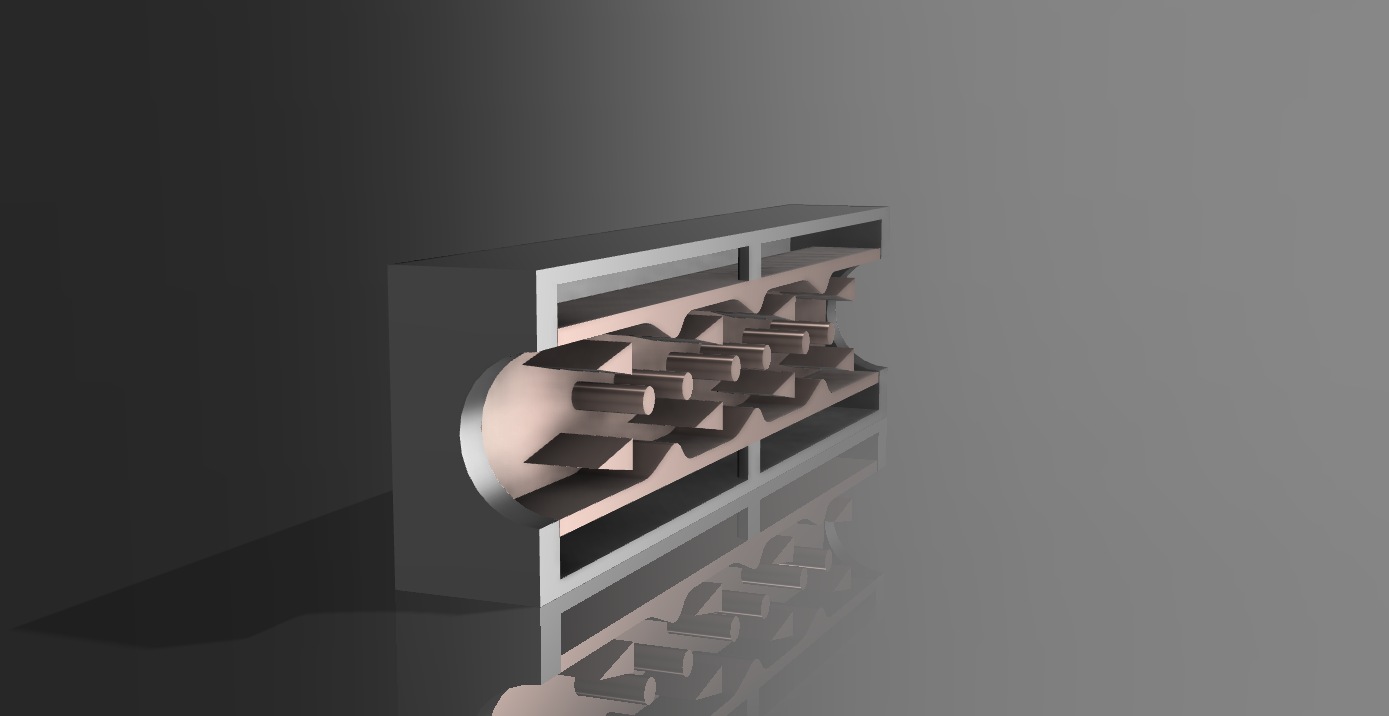

Design Features

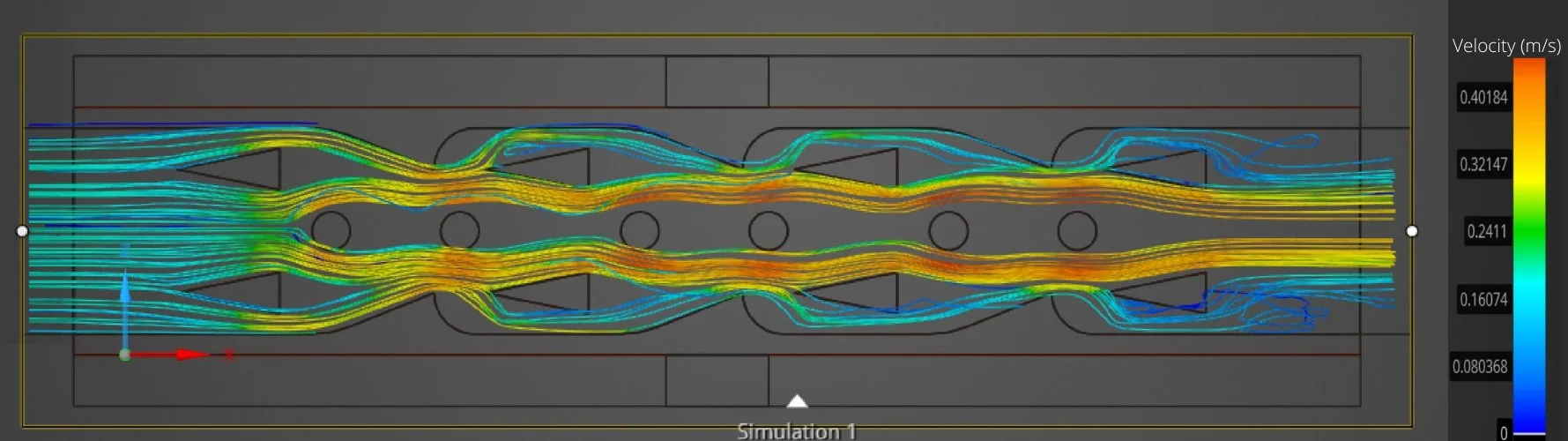

To increase the rate of conduction, we maximized the surface area of the internal heating element by adding many redirections inside of the faucet. We made these redirections as smooth as possible to minimize pressure loss. Iterating through simulations, we optimized our inlet velocity and internal geometry.

Analysis and Conclusion

Our analysis showed an increase in the power needed to operate the heated faucet compared to a traditional water heater, but accounting for the reduced operating time, the energy used is significantly less. For a simulated family of four’s water usage, the on-demand water heater leads to a net energy reduction of about 50%, resulting in nearly $600 annual savings in energy alone (in California).